If you are thinking about buying a pair of boots, one of the best choices you can do is trusting in Sendra Boots. At Corbeto’s Boots we count more than forty years working together with the Spanish brand, to the point of cooperating with Sendra Boots design team creating new styles to adapt our customer’s demands and current trends.

Sendra Boots distributes in countries such as United States, France, Italy, Germany, United Kingdom and many more. Sendra cowboy boots are internationally recognized by their designs, quality, and finish and it isn’t strange seeing them in fashion magazines or big catwalks like New York fashion week. But being prestigious fashion designers’ favorites doesn’t make Sendra a comercial brand that take its products lightly. It also is one of the preferred brands by country and line dance passionate, western fans and even, rodeo cowboys. The reason is simple: at Sendra, the boots have been made following the highest quality standards.

Sendra Boots, a 250 steps production process

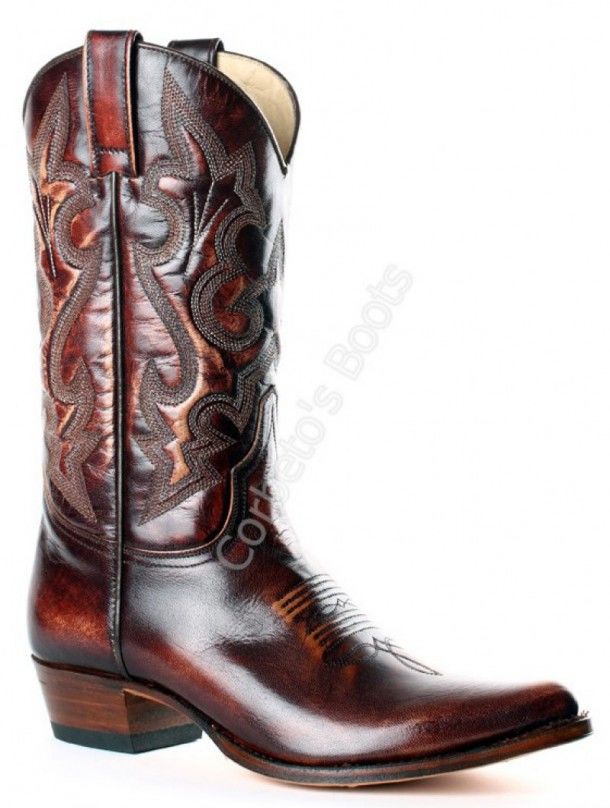

To create a pair of Sendra boots, ankle boots, or shoes is a craftsman and laborious process consisting in 250 steps. A combination of tasks that include designing, cutting and mold the leathers, embroider and cut motives for its design, put together all the elements and provide each boot the perfect finish.

The first step is raw materials selection. At Sendra Boots won’t find synthetic leathers, only a selection good quality leathers. These leathers are molded by artisan’s hands to shape the shoe last. And even in the diverse rivets, we can observe Sendra Boot’s effort to reach the highest quality.

The trim of each boot is one of the most important steps. From it depends to feel more comfortable when getting them on, so, is necessary to inspect all the sewing. After, toe boxes and heel counters are added by pression and heat apply to give each piece more resistance

It is also important to point out the using of cork as inside bottom filling that works as natural cold isolation and makes the insole to adapt our step, also the steel shank to confer greater robustness to heel and sole’s junction point. Although, there is a step that deserves to be explained with more details: the Goodyear welt system.

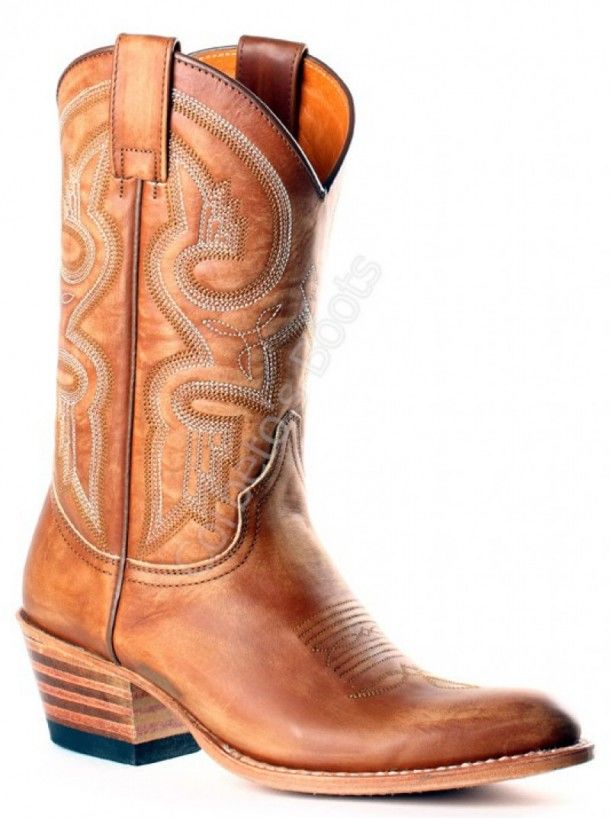

Goodyear welt, resistance and durability synonym

In 1919 Sendra brothers purchased the first Goodyear system machine. Not much later than it was developed by the United Shoes Machinery. Since then, Sendra Boots is one of the few brands able to elaborate its footwear with this patented system.

Goodyear welt system provides the boot an extraordinary resistance and durability as well as increasing the comfort and feet’ support and work as thermal insulation. It consists in a double welt that joins the leather with boot’ sole. While an internal welt holds the upper leather to the insole and turns it, an external welt joins the panel to the outsole. This way, the whole sole is formed by two soles with a layer of cork filling. Very few boots are as comfortable and resistant like Sendra cowboy boots.

This system expands to all footwear Sendra does: from the cowboy boots, to the engineer boots, from ankle boots to Sendra shoes.

Corbeto’s Boots, Sendra Boots official dealer

We at Corbeto’s feel proud to offer a wide assortment of western and engineer boots, or biker boots for men and women. But at our store at Las Ramblas like at our online shop you can find a broad variety of Sendra products: from the typical campero’s to the most exotic cowboy boots, going through ankle boots, shoes, belts, belt buckles and diverse boot accessories.